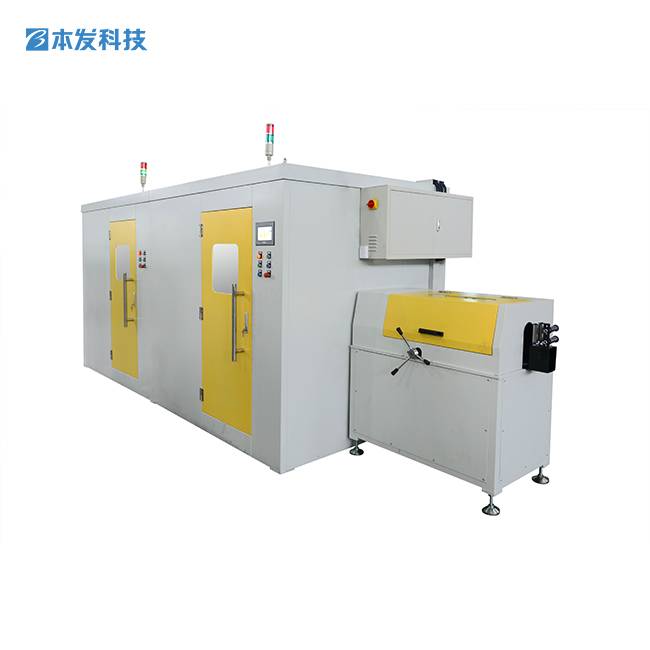

Short Lead Time for Tubes Crimping Machine - Nipple And Sleeve Assembly Machine BFZP-C1 – BENFA

Short Lead Time for Tubes Crimping Machine - Nipple And Sleeve Assembly Machine BFZP-C1 – BENFA Detail:

BF Series Assembly sleeve core and nut machine

Zhejiang Benfa Technology Co.,Ltd working on R&D BF series hose braiding machine , automatic hose cutting machine ,braided hose assembly machine .It can be applied in high&low pressure hose ,Car and motor bike rubber hose ,brake hose ,spray rubber hose factory .

The assembly machine apply the PLC ,HMI, pneumatic cell , mechanical straight motion ,the motion precision ,safety, easily operated ,maintain easily . The assembly machine come true automatically transport sleeve core and nut ,assemble the sleeve automatically ,half automatic assemble sleeve and nipple , automatic injection the nipple ,finished product automatically pull. The solve the braided wire easy loose, sleeve not in position , hard assemble core and nut ,braided wire broken finger . enhance production efficiency . working speed: 460-540 pcs per hour ,loosen the labour intensity. improve the product quality.

Techincal Parameter

|

Type |

BFZP-C1 |

|

Voltage |

220V |

|

Power |

1000W |

|

Air pressure |

0.3-0.5Mpa |

|

Working Efficiency |

30Pcs/Min |

|

Dimension |

1200*1100*1400mm |

|

Weight |

450kg |

|

Function |

Assemble sleeve core and nut |

Product detail pictures:

Related Product Guide:

Blackmagic external GPU review: A very Apple graphics solution | Polyester Yarn Winding Machine

Switzerland : Uster cotton contamination control a hit in Texhong group | Slitting And Spool Winding Machine

Innovation, quality and reliability are the core values of our company. These principles today more than ever form the basis of our success as an internationally active mid-size company for Short Lead Time for Tubes Crimping Machine - Nipple And Sleeve Assembly Machine BFZP-C1 – BENFA, The product will supply to all over the world, such as: Algeria, Sao Paulo, Bolivia, Our monthly output is more than 5000pcs. We have set up a strict quality control system. Please feel free to contact us for further information. We hope that we can establish long-term business relationships with you and carry out business on a mutually beneficial basis. We are and will be always trying our best to serve you.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.