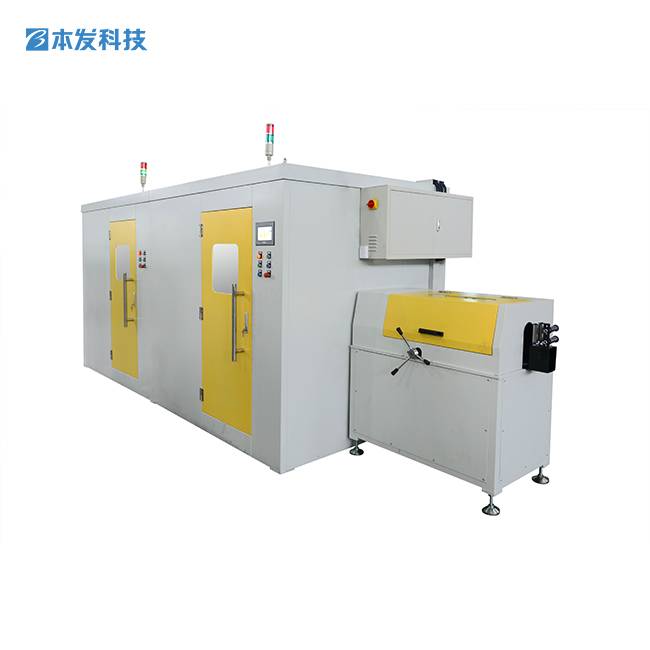

New Delivery for Automatic Cone Yarn Winding Machine - Sanitary Hose Assembly Machine BFZP-X2 – BENFA

New Delivery for Automatic Cone Yarn Winding Machine - Sanitary Hose Assembly Machine BFZP-X2 – BENFA Detail:

Zhejiang benfa technology Co.,Ltd working on R&D BF series hose braiding machine , automatical hose cutting machine ,braided hose assembly machine .It can be applied in braided hose ,Car and motor bike rubber hose ,brake hose ,spray rubber hose, washer car hose machine factory .

The assemble machine apply the PLC ,HMI, pneumatic cell , mechanical straight motion ,the motion precision ,safety ,easy operation ,maintenance easy . The assemble machine come true automatically transport sleeve ,assemble the sleeve automatically ,semi automatic assemble core and nut , automatic injection the core. ,finished product automatic pull. Solve the braided wire easy loose, sleeve not in position , hard assemble core ,braided wire broken finger . enhance production efficiency . working speed: 660-740pcs per hour ,relieve the labour intensity. Enhance the prodcut quality.

Technical Parameter

| Type | BFZT-A |

| Voltage | 220V |

| Power | 500W |

| Air pressure | 0.3-0.5Mpa |

| Working Effciency | 60Pcs/Min |

| Dimension | 800*600*1400mm |

| Weight | 150kg |

| Function | Assemble sleeve |

Product detail pictures:

Related Product Guide:

The Evolution of the Baseball From the Dead-Ball Era Through Today | Bleacher Report | Slitting And Spool Winding Machine

Accrington firm to pump £400k into expansion plans | Wire Braiding Machine

Every single member from our higher effectiveness product sales staff values customers' requires and organization communication for New Delivery for Automatic Cone Yarn Winding Machine - Sanitary Hose Assembly Machine BFZP-X2 – BENFA, The product will supply to all over the world, such as: Curacao, Greece, Czech, Our product quality is one of the major concerns and has been produced to meet the customer's standards. "Customer services and relationship" is another important area which we understand good communication and relationships with our customers is the most significant power to run it as a long term business.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!