Factory Outlets Sed Circular Knitting Machine - Factory For Industrial Custom Winder Wool Winders Cotton Yarn Doubling Machine – BENFA

Factory Outlets Sed Circular Knitting Machine - Factory For Industrial Custom Winder Wool Winders Cotton Yarn Doubling Machine – BENFA Detail:

Good quality To start with,and Purchaser Supreme is our guideline to offer the top service to our customers.Presently, we’ve been seeking our best to be amongst the top exporters inside our industry to fulfill consumers extra need to have for Factory For Industrial Custom Winder Wool Winders Cotton Yarn Doubling Machine, Any interest, remember to really feel absolutely free to make contact with us. We’re hunting forward to forming prosperous small business relationships with new consumers within the environment while in the in the vicinity of long term.

Good quality To start with,and Purchaser Supreme is our guideline to offer the top service to our customers.Presently, we’ve been seeking our best to be amongst the top exporters inside our industry to fulfill consumers extra need to have for Cotton Yarn Doubling Machine, Wool Winders, Yarn Winder Machine, Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

Introduction

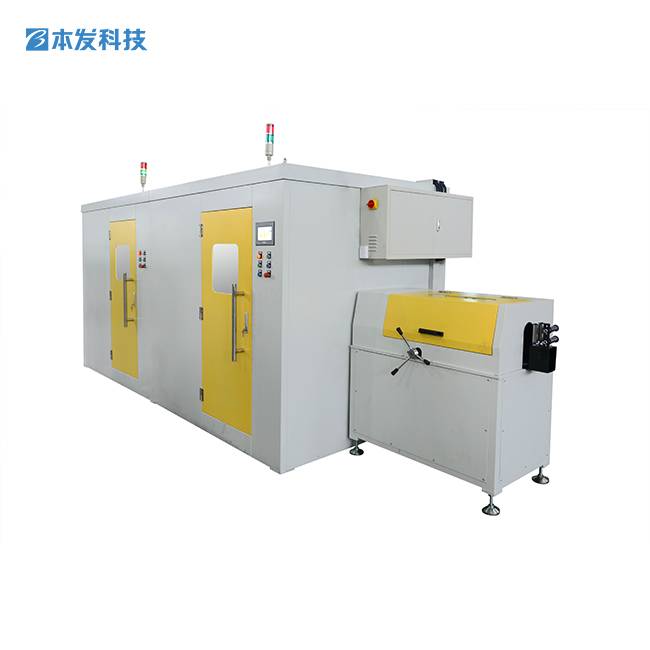

BFB-W series single or double horizontal high speed braiding machine is adopt advantage braiding technology, such as human machine interface ,inverter control and PLC control cell ,auto lubricant ,transmission gear in –phase ,pneumatic and hydraulic pressure design .the braiding machine can come true single or double braiding . Our braiding machine can be used in high pressure rubber hose .auto motor hose ,auto drive turning hose ,brake hose ,apply the brake hose ,auto air condition hose ,cable and industrial rubber hose ,plastic hose enhanced braiding .

Features:

1 One person can operation several machines .when the bobbin empty ,wire broken the machine will stop .the alarm flicker

2 Operational easy ,digital display Setting pitch by digital control. The machine run display by the digital display

3 Automatic ,Advantage technology , adopt human machine interface ,PLC control cell coder, inverter control ,counting function ,operation.

4 Good quality ,high efficiency .Often used operation button outside fixed .The efficiency is twice other type braiding machine

5 Design is reliable ,good out look

6.Less noise ,produce precision spare parts ,good material and heat treat and ,sound proof

7.Stock braiding data , function .Braiding parameter and production total can be stocked in braiding machine system

Parameters

| No spindle | 20 Spindle | 24 Spindle | 36 Spindle | 48 Spindle | 64 Spindle | 96 Spindle | 112 Spindle |

| Material | Wire 0.16-0.5mm Stainless steel wire 0.18-0.5mm | ||||||

| Bobbin cubage | OD D=84mm ID d=32mm HIGH H=202mm Cubage 956cm3OD D=78mm ID d=32mm HIGH H=152mm Cubage 603cm3 | ||||||

| Spindle RPM | 40RPM | 35RPM | 25RPM | 17.5RPM | 12RPM | 7.8RPM | 6.75RPM |

| Braiding stands | 3-15股 | ||||||

| Braiding power | 4.0KW | 4.0KW | 5.5KW | 7.5KW | 11.0KW | 18.0KW | 22.0KW |

| Traction power | 1.1KW | 1.5KW | |||||

| Spindle spring | 5-15KG | ||||||

| Braiding hose diameter | ≤22mm | ≤30mm | ≤50mm | ≤80mm | ≤150mm | ≤230mm | ≤350mm |

| Weight | 1500kg | 1575kg | 2750kg | 3200kg | 4230kg | 5600kg | 7600kg |

Product detail pictures:

Related Product Guide:

CMO’s top 10 martech stories for the week – 28 June 2018 | Wire Braiding Machine

Fabrication methods (2015) : CompositesWorld | Slitting And Spool Winding Machine

We have probably the most state-of-the-art output equipment, experienced and qualified engineers and workers, recognized good quality manage systems plus a friendly skilled income workforce pre/after-sales support for Factory Outlets Sed Circular Knitting Machine - Factory For Industrial Custom Winder Wool Winders Cotton Yarn Doubling Machine – BENFA, The product will supply to all over the world, such as: Puerto Rico, Canberra, Curacao, Due to good quality and reasonable prices, our items have been exported to more than 10 countries and regions. We are looking forward to cooperating with all customers from at home and abroad. Moreover, customer satisfaction is our eternal pursuit.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!